This post contains affiliate links. Click here to read my affiliate policy.

Last Updated on December 8, 2023

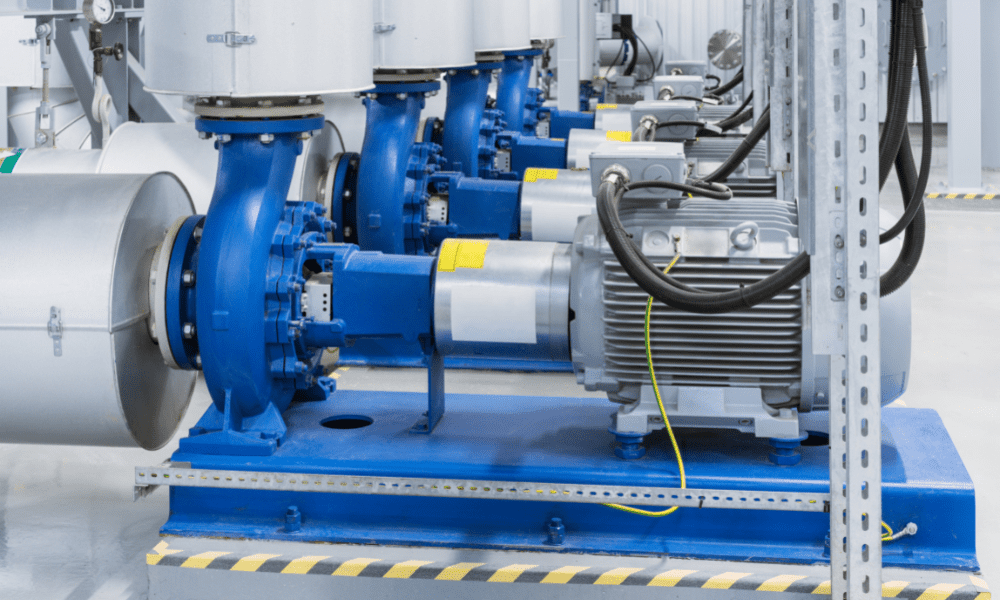

A rotary vane pump falls into a category of positive displacement pumps, which provide a constant flow of a given fluid at a fixed speed. This pump is, therefore, mainly used in areas where a continuous flow of an element, air or liquid is required. This could range from automobiles, cooling systems and, in this case, food production.

How Do Vane Pumps Work?

To understand the concept of vane pumps in the food industry, one needs to know how the machines work. The pump has a component known as a muffler box which has an inlet on top of it. This is where fluid flows into the pump’s suction port, which is the pump’s most central area.

The spaces in the suction port are divided by four vanes. Fluid fills up from the suction port onto one of the vane spaces at any given period. As the rotor rotates, the vanes turn, and the discharge port is opened with the trapped fluid released to the port.

This concept causes this type of pump to be referred to as a positive displacement pump. Due to its fantastic ability to discharge an equal volume of elements at any given time, its applications are numerous.

Application In The Food Industry

Packaging

One of the most critical applications of the vane pump is in the packaging industry. A packing company, particularly those involved in food production, has recognized the importance of vacuum sealing their products to extend their shelf life. In this context, the vane pumps are instrumental in displacing air to ensure that all units are sealed uniformly at a specific pressure level, thus guaranteeing a longer preservation period.

This process not only maintains the food’s overall structure but also retains its moisture and flavor. Food items such as vegetables and fruits, when vacuum-sealed and stored under low temperatures, have been known to last for years. By sealing them in this manner, an anaerobic environment is created, inhibiting the growth of bacteria due to the absence of oxygen. Hence, vane pumps, in conjunction with packing companies, play a pivotal role in ensuring the preservation of food quality and extending its shelf life.

The food industry is almost always under a lot of pressure to produce many equal units free of pathogens or bacteria in the shortest period. For this reason, many bottling companies will use the vacuum to equalize pressure and allow for equal fluid movement. The firms will mostly use modified rotary pumps in stainless steel for this application.

Bottling companies have reported rotary vane equipment to be simple, reliable and durable, registering up to 6480m³/h displacement in large machines. They are modified and designed to save costs and resources, such as energy in power usage. The machines are also notably low maintenance with minimal repairs required, and have proven to be the cheapest long-term solution.

Dairy Products

Rotary pumps have been used constantly to pump viscous dairy products through designated pipes. This includes sour cream, condensed milk, yogurt and ice cream mixtures. Food companies specializing in the production of dairy products use rotary vane pumps to move products of this kind of viscosity for usage within the site or packaging.

Espresso Machines

Smaller versions of rotary vane pumps are used in espresso machines which are directly attached to a water source. One of the main advantages is that vane pumps are relatively silent with minimal vibrations. This is ideal in an espresso machine used for commercial purposes since the setting of it could be in a restaurant or open area.

Moreover, the rotary vane pumps in espresso machines tend to respond quicker by producing instant pressure. The pumps also make more units per given time compared to other pumps used in different machines. Restaurant owners use this to guarantee less downtime and more units produced to ultimately realize profits.

Chocolates And Sweets

The realization of modified vane pumps to transfer and package chocolates and sweets came as a relief for food production companies dealing with these kinds of products. This is because the fluids are mainly mixtures of eggs, butter and cocoa, which, if pumped too quickly, can cause them to start separating. The viscosity was also a cause for concern since cooling or overheating it can cause it to clog the pipes and create damage.

Specialized vane pumps offer solutions to all these problems by producing a low rpm, ensuring the mixtures stay in their original state during movement. These pumps are also designed with different materials that ensure the fluid is maintained in its viscous state without solidifying and are cleanable. Pressure is also held at not more than 7 bars to ensure that the mixture’s ingredients don’t separate.